Lvyuan Industrial Filtration Solution

ShIP to

Lvyuan Industrial Filtration Solution

ShIP to

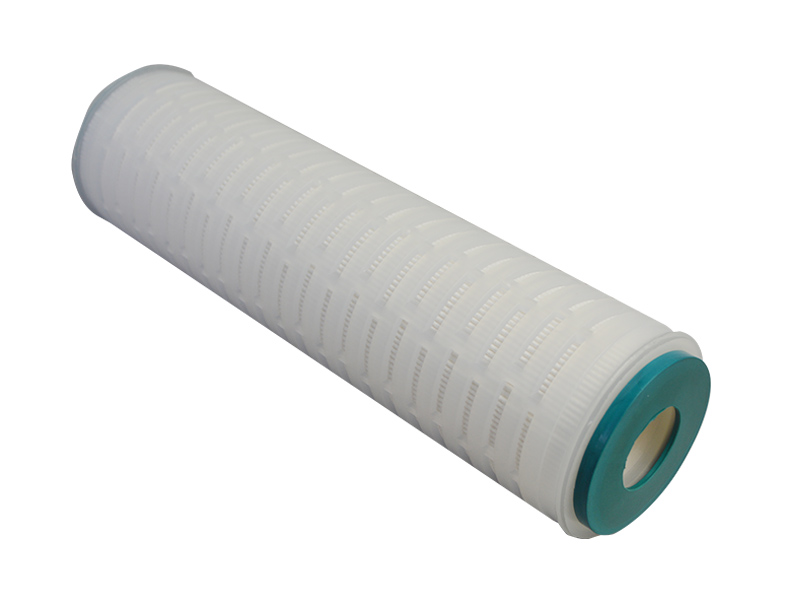

Product Feature

◪ Excellent hydrophobic performance, the water erosion is more resistant than the common PVDF membrane.

◪ Withstand water shock, back pressure and repeated high temperature sterilization.

◪ 100% bacterial retention & effective filtration to 0.2 μm particle.

◪ 100% integrity tested.

◪ It is constructed of 2 kinds of hot welding materials(PTFE & PP), not any adhesives, clean & stable, meet the high standards of pharmaceutical industry.

| Product Name | 10 inch PTFE membrane pleated filter cartridge with stainless steel 222 |

| Filter media | PTFE membrane |

| Support | PP/Polypropylene |

| Core/End cap | PP/Polypropylene |

| Seal material | Silicone/EPDM/VITON/PTFE/NBR/TEFLON |

| Outer diameter | 2.7‘’(69mm) |

| Length | 9.75'', 10'', 20'', 30'', 40'', Customized |

| End cap | 215/222/226/FIN/DOE/SS |

| Filtration area | ≥0.72m² |

| Max.operating temperature | 80℃, 0.173Mpa |

| Micron rating(μm) | 0.2, 0.45 |

Reverse osmosis water system prefiltration

Copyright © 2019 Guangzhou Lvyuan Water Purification Technology Co., Ltd. | All Rights Reserved Design

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist