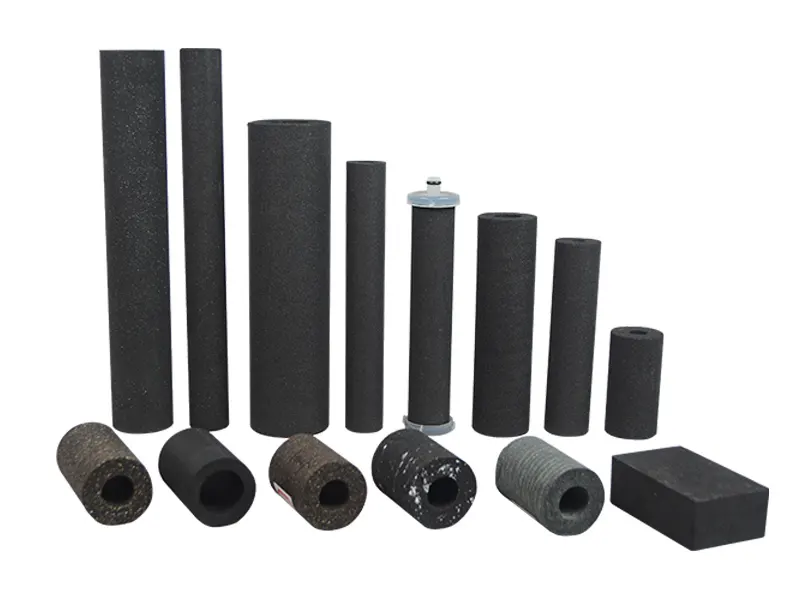

activated carbon sintered metal filter supplier for food and beverage

Product Feature

◪ Large filtration area, strong absorption capacity, high flow rate.

◪ High dirt holding capacity, low drop out, high filtration efficiency.

◪ Fits to all standard filter housings or sport bottles.

◪ High iodine value activated carbon materials

◪ Effectively remove bad smells, colors, chlorinated compounds, VOCS and THMS;

◪ Long service life

Product Parameter

| Fiter Cartridge dimensions | |

| Outer diameter | 14, 16, 19, 25, 28, 30, 35, 38, 40, 45, 46, 50, 53, 55, 60, 63, 64, 67, 70, 76, 90, 96.5, 103, 105, 121mm |

| Inner diameter | 6, 8, 10, 12, 14, 16, 18, 20, 22, 25, 28, 30, 32, 35, 38, 40, 45, 50mm |

| Length | 5’’ (125mm), 10’’ (250mm), 20’’ (500mm), 30’’ (750mm), 40’’ (1000mm) |

| Other dimensions | Customized by customer’s request. |

| Material of constructions | |

| Filter media | Coconut shell carbon, coal carbon |

| Enc caps | Polypropylene |

| Netting | Polypropylene |

| Gasket/oring material | Silicone, EPDM, NBR, Viton |

| Performance | |

| Removal rate | 5, 10, 25 um |

| Maximum Operating Temperature | ≦ 80℃ |

| Maximum Operating Pressure | 10 bar |

| Maximum differential pressure | 7 bar at 25℃ |

Product Details

Product Applications

Quick link

Products

Stainless Steel Filter Housing

Sediment Filter

Sintered Metal Filters

Melt Blown Filter Cartridge

High Flow Filter Cartridge

Pleated Filter Cartridge

Sintered Filter Cartridge

Sintered Porous Plastic

Pipette Tips

Medical Filters

Contact Us

About us

Our Lvyuan Fliter always insists on product quality is life, our aim is to provide more professional and attentive cartridge filter, filter housing and services for our global customers.

+86 15975359293