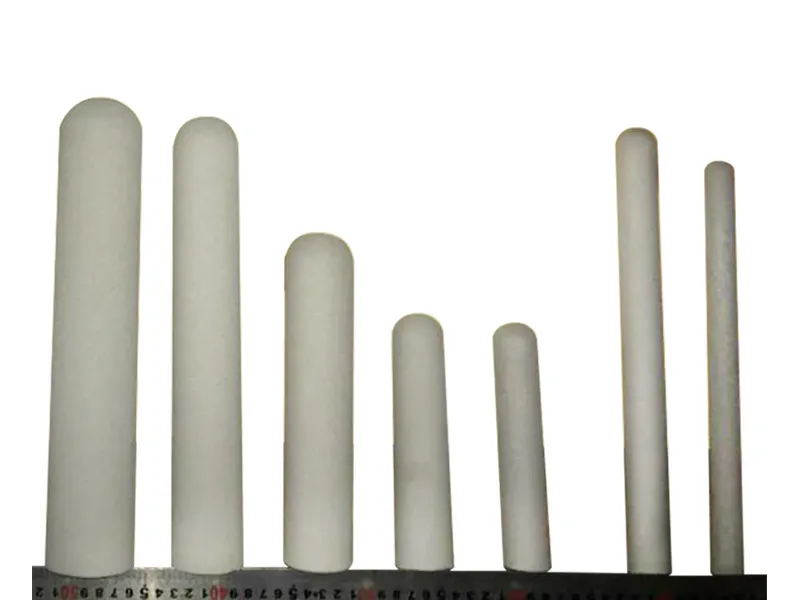

porous sintered stainless steel filter rod for industry

1. Guangzhou Lvyuan Water Purification Equipment Co., Ltd. uses environmentally-recyclable materials as much as possible for sintered stainless steel filter .

2. This product is highly regarded among customers, with high durability and high cost performance.

3. One can benefit from the portability of this product, and the ability to create an extremely environmentally-efficient, self-sufficient living space.

4. With such high efficiency, the product is therefore essential in many industries. It can ensure the necessary agility of processes and to produce as efficiently and profitably as possible at the same time.

Product Feature

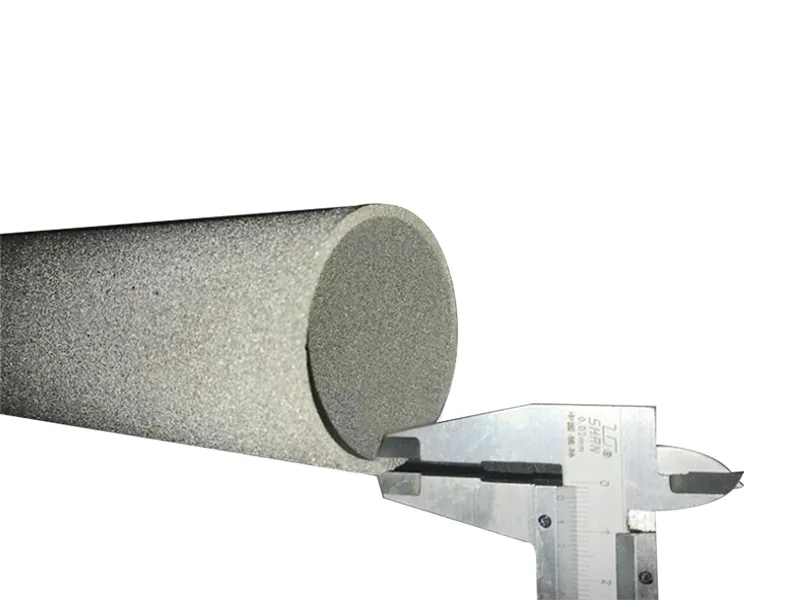

◪ Uniform structure, narrow pore size distribution, and high separation efficiency.

◪ High porosity, the resistance of filtration less, and the penetration efficiency is high.

◪ High temperature resistant, it can be normally used below in 280 degree.

◪ Good chemical stability, acid & alkali corrosion resistance, and oxidation resistance.

◪ Good mechanical performance, it can have the suction filtration and press-filtration, simple operation.

◪ Low differential pressure, the area of cover is small, and large water flow rate;od mechanical performance, it can have the suction filtration and press-filtration, simple operation.

◪ Strong antimicrobial ability, no microbes.

◪ The finished-products technology is good, the overlength of overall length can be reached to 1000mm.

◪ It can be on-line regeneration, easy to clean, and long service life.

◪ No particles fall off, it will not make the concentrate form secondary pollution, it conforms to be food hygiene and pharmaceutical GMP requirements.

Product Parameter

| Fiter Cartridge dimensions | |

| Length | 5’’ (125mm), 10’’ (250mm), 20’’ (500mm), 30’’ (750mm), 40’’ (1000mm) |

| Diameter | Ø22, 30, 50, 60, 70, 80, 100, 120mm |

| Other dimensions | Customized by customer’s request. |

| Material of constructions | |

| Filter media | Titanium |

| Connector type | Flat, Insert type, Thread type, Fin |

| End caps | DOE, 215, 222, 226, M20, M30, M42 or as request. |

| Sealing material | Silicone, NBR, EPDM, Fluoro rubber, etc |

| Performance | |

| Removal rate | 0.1, 0.45, 1, 3, 5, 10,20, 30, 40, 50, 100um |

| Porosity | 28-50% |

| Temperature Tolerance | ≦ 300℃ wet |

| Permeability | 0.02-20L/cm2 min Pa |

| Maximum Operating Pressure differential | 6.0 bar |

| Flow rate (L/H) | 180, 200, 250, 280, 300, 350, 500, 800, 1000, 1500, 1600 |

◆◆Pure water flow rate reference table: the initial value of 10'' sintered titanium cartridge (P=0.2 MPa, 1cP, 25℃)

| Micron rate (μm) | 0.2 | 0.45 | 1 | 2 | 3 | 5 | 10 | 20 | 30 |

| Flow rate (L/H) | 180 | 200 | 250 | 280 | 300 | 350 | 500 | 800 | 1000 |

Product Details

Product Applications

Company Features

1. As a reliable manufacturer and supplier, Guangzhou Lvyuan Water Purification Equipment Co., Ltd. has won trust in sintered stainless steel filter market.

2. The strict pursuit of Lvyuan to quality motivates us to utilize the advanced technology to produce sintered filter cartridge .

3. Over the years, we have been dedicating to producing more environmental-friendly products. We are working on seeking recyclable or non-polluted materials that pose no negative impact on our environment. It is our aim to meet the social responsibility our company has. We will keep working to ensure that our products and services act in accordance with the principles of sustainability. We embrace sustainability all the time. We invest in automation technologies and continuously work to reduce our carbon footprint across the value chain. To achieve sustainability, we will adopt the latest green manufacturing technology. We believe the application of the technology will improve sustainability and efficiency no matter in production methods or resource use.

Quick link

Products

Stainless Steel Filter Housing

Sediment Filter

Sintered Metal Filters

Melt Blown Filter Cartridge

High Flow Filter Cartridge

Pleated Filter Cartridge

Sintered Filter Cartridge

Sintered Porous Plastic

Pipette Tips

Medical Filters

Contact Us

About us

Our Lvyuan Fliter always insists on product quality is life, our aim is to provide more professional and attentive cartridge filter, filter housing and services for our global customers.

+86 15975359293