What should be paid attention to when choosing

by:Lvyuan

2021-01-25

When selecting stainless steel filter elements, what should we pay attention to? In addition to price considerations, what other aspects should we pay attention to? Let us listen to the introduction of professionals.

First of all, before selecting stainless steel filter elements, buyers should clarify the application location and area of ??the product. These two aspects are particularly important. The application situation is conducive to clarifying which product to buy. The size of the used area determines the size of the product. The application of these two aspects to purchase products can improve the quality of purchase. Buyers can also tell the merchants these two requirements directly, and experienced sales staff will recommend suitable products according to your requirements. In fact, if the product purchaser lacks purchasing experience, they can tell them their purchasing needs in a variety of ways. The products recommended by experienced product salespeople may be better than the products they blindly selected.

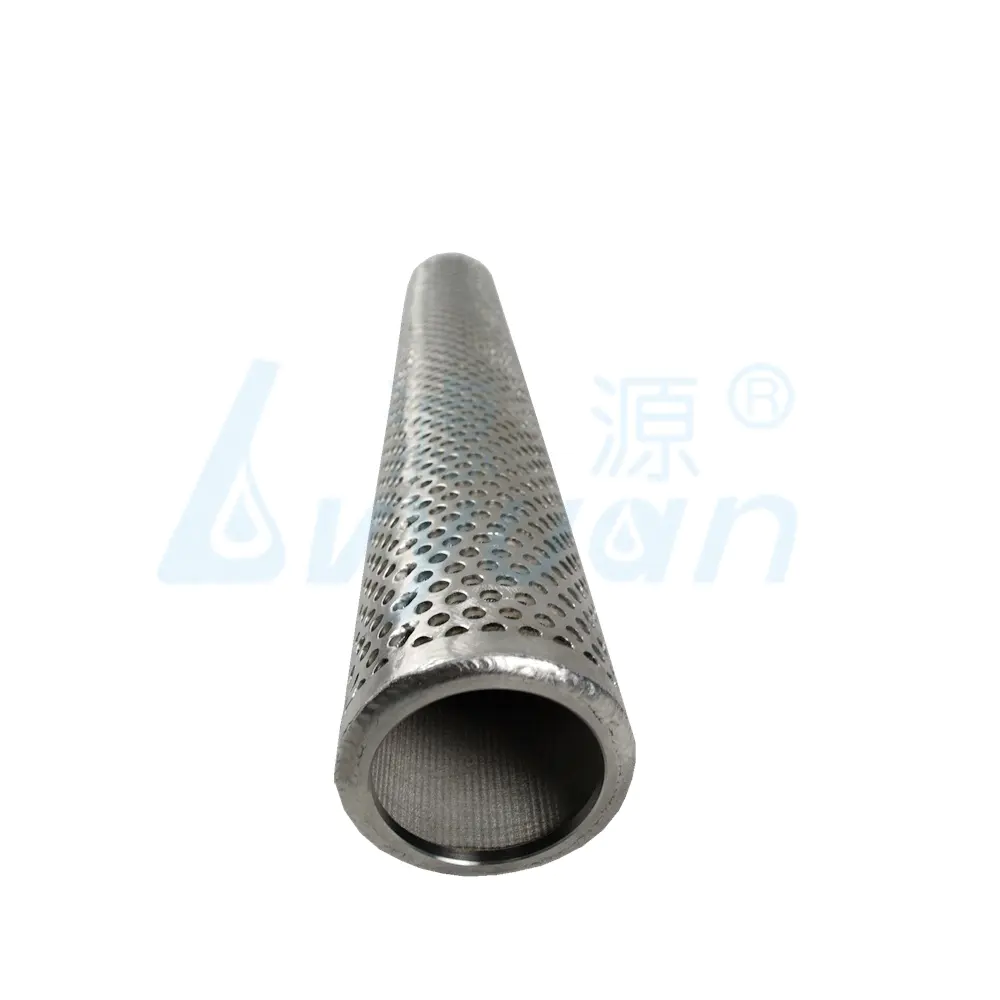

Stainless steel filter element

In addition, when purchasing stainless steel filter elements, not only must pay attention to the status quo, but also the later maintenance of the product, which is usually ignored by the purchaser. The after-sales service of a product is the key to guaranteeing the service life of the product, as important as the quality of the product itself. It is difficult to guarantee that failures will not occur in the application of good products, so reliable after-sales service is the key to product maintenance. Therefore, in the process of purchasing stainless steel filter elements, buyers should ask about the after-sales requirements and procedures of their products to meet their needs from time to time.

In addition, it is the purchase price of the product, which is an issue that customers care about. In fact, the retail price profit margin of the product is particularly limited, so buyers try to buy in batches to get the merchant's profit price.

These are all issues that need attention in the procurement of stainless steel filter elements. I hope that friends who need to purchase in this regard can learn from them. I also hope that you can be more patient and cautious when choosing, so that you can make the right choice and choose the right product.

How to maintain the stainless steel filter element correctly?

The application of stainless steel filter elements has become more common with economic progress, but many people don't know much about the performance of the product, and they know less about its maintenance. Many people think that it will never rust and has excellent corrosion resistance. This is because it forms an oxide film on the surface, which exists in the form of a more stable oxide in nature. In other words, although stainless steel filter elements have different oxidation levels depending on the application conditions, they are all oxidized. This phenomenon is generally called corrosion. Next, the editor will introduce to you how to maintain it to reduce corrosion.

If there is dust on the surface of the product and the dirt is easily removed, it can be cleaned with soap, weak detergent or warm water. The trademark and film on the surface of the stainless steel filter element should be washed with warm water and weak detergent, and the binder component should be scrubbed with alcohol or organic solvents (ether, benzene).

Stainless steel filter element

The grease, oil and lubricating oil on the surface of the product should be cleaned with a soft cloth, and then cleaned with a neutral detergent or ammonia solution or a special cleaning agent. The surface of the stainless steel filter element has bleach and various acids attached. It should be rinsed immediately with water, then dipped in ammonia solution or neutral carbonated soda water solution, and washed with neutral detergent or warm water.

The rainbow pattern on the surface of the product is caused by excessive application of detergent or oil. It can be washed away with a mild detergent in warm water. The rust caused by the dirt on the surface of the product can be cleaned with 10% nitric acid or abrasive cleaners, or with special cleaning chemicals. As long as we apply the correct maintenance methods, we can increase the service life of the product and maintain its clean, bright and gorgeous style.

When cleaning the surface of the stainless steel filter element, be careful not to scratch the surface and prevent the application of bleaching ingredients and abrasive detergents, steel balls, grinding tools, etc., to remove the detergent, rinse the surface with clean water after cleaning.

The characteristics, applications and maintenance methods of stainless steel filter elements

Characteristics and application of stainless steel filter element

The product characteristics of stainless steel filter element can be divided into the following points:

(1) Excellent chemical compatibility, suitable for filtering strong acids, strong alkalis and organic solvents.

(2) The filter membrane is a pleated deep-layer filtration with a large membrane filtration area.

(3) Low pressure difference, strong dirt holding capacity and long service life.

(4) There is a wide filter precision to choose the application field of the filter element.

(5) Pharmaceutical industry: pre-filtration of various antibiotic liquids.

(6) Food and beverage industry: filtration of alcohol, mineral water and drinking water.

(7) Petroleum industry: oilfield water injection filtration.

(8) Electronics industry: high-purity water pre-filtration.

(9) Chemical industry: filtration of various organic solvents, acids and lyes.

The stainless steel filter element is resistant to general acid, alkali and organic corrosion, and is especially suitable for sulfur-containing gas filtration. With high strength and good toughness, it is more suitable for high-pressure environments.

Material: 304, 304L, 316, 316L and other stainless steel metal woven wire mesh, wire cloth, copper mesh, nickel mesh, galvanized square mesh, black wire cloth, mat mesh, round hole mesh, sheet metal perforated mesh, expanded metal mesh , Special high temperature resistance, alkali resistance, wear resistance filter screen.

Application classification: dust filter cartridge, dust filter cartridge, waterproof filter cartridge, solid-liquid separation filter cartridge, air filter cartridge, light filter cartridge, vapor-liquid filter cartridge, water filter cartridge, chemical liquid filter cartridge, lubricant filter cartridge, oil-water separation Filter cartridges, lampblack filter cartridges, high efficiency filter cartridges, high temperature resistant filter cartridges, low temperature resistant filter cartridges, dry filter cartridges, stainless steel filter cartridges, punching filter cartridges, etc., high efficiency filter cartridges, etc.

Main uses: Mainly used in environmental protection, chemical, food, pharmaceutical, petroleum, water treatment and other filtration industries, air conditioners, range hoods, washing machines, automobile starting systems, fuel tanks, filter pots, fans, sinks, air purifiers, water pumps, faucets, Medical, paint room, aquarium, vacuum cleaner, coffee machine, centrifuge, compressor, placement machine, water purifier, drinking machine, filter, excavator, sugar and other industries; our factory can produce and A variety of mechanically matched special-shaped filter cartridges, such as cone, wedge, basket, V-shaped, cylindrical, etc., the material and density of the filter can be customized according to requirements, quality assurance, and price discount.

Features: acid and alkali resistance, high temperature resistance, abrasion resistance, not easy to damage, after filtering and cleaning, it can be used repeatedly.

Maintenance method of stainless steel filter element

When the stainless steel filter has not been used for a long time, we must drain the filtrate inside the filter clean, then take out the filter element, wash and dry the process, when the series of operations are completed, put the product into a clean plastic bag Inside and sealed, this is to ensure that the filter element product is not contaminated. Finally, wipe the stainless steel filter and store it in a dry place.

Generally, the replaced filter element should be immersed in a strong acid lotion for about twenty-four hours. Remember, the temperature of the acidic liquid should be kept at about 25-50 degrees! ! ! During the soaking process, the author recommends that the proportion of acid and alkali in the liquid should be controlled between 20%. This is to avoid damage and pollution of the inside of the filter element by the liquid. Generally speaking, a lotion with a higher protein factor is the best, and the effect is very good in terms of cleanliness and economy! Therefore, an enzyme solution with a higher protein content should be used for cleaning. After cleaning, it must be cleaned twice, and steam is used for overall disinfection. This process is the most important for the maintenance of the filter.

The stainless steel filter should pay attention to a certain time and temperature during the disinfection process. Generally, the internal filter product should be placed in the disinfection cabinet at 130℃/20 minutes. The disinfection temperature should not exceed 150℃, and the maximum disinfection time should not exceed 30 minutes. It must be remembered that once the sterilization temperature is too high, or the time is long, and the pressure is high, it will cause the overall damage of the internal components of the filter (filter element).

Custom message